Services

Healthy

Food

Edible Coatings

High-Barrier Packaging

Prevents Contamination

ECO

Friendly

Not Harmful To The Environment

Bio Composite Solutions

Make A Water-Based Solution

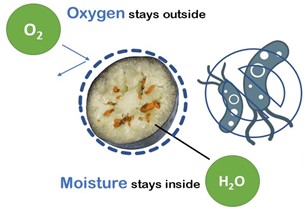

HOW BERRYCOAT WORKS

- Coating barrier stops gas transmission

- Retains moisture, flavor and firmness

- Preserves nutrients

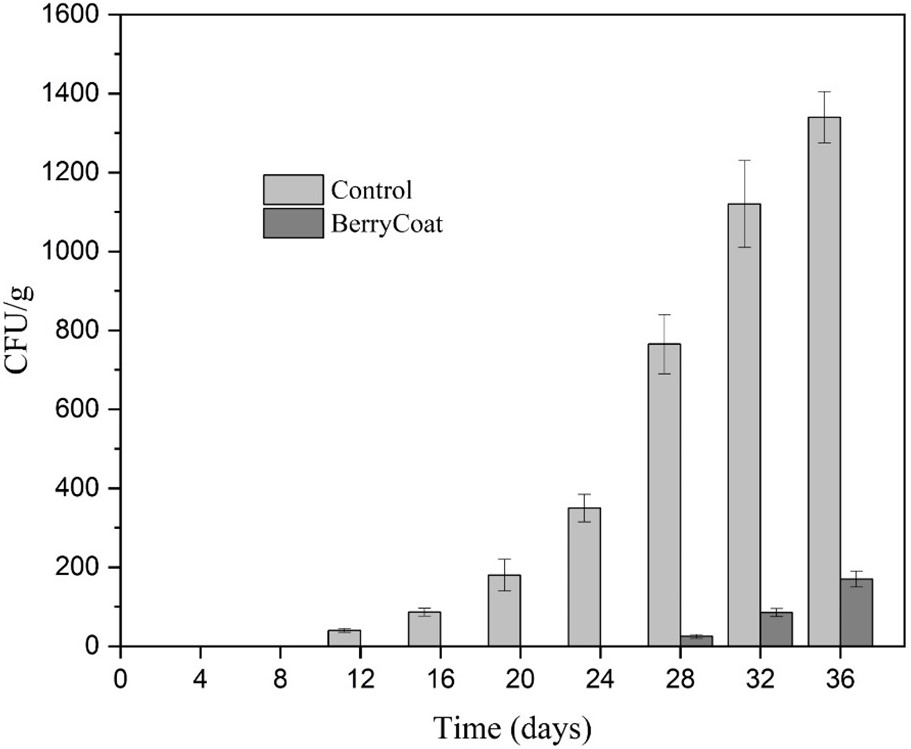

- Strong antimicrobial/antifungal properties

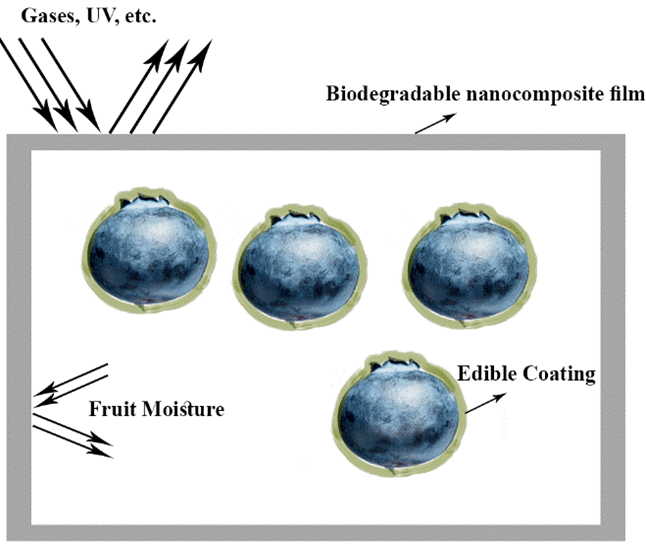

- Nanocomposite packaging stops gas transmission and reduces moisture loss

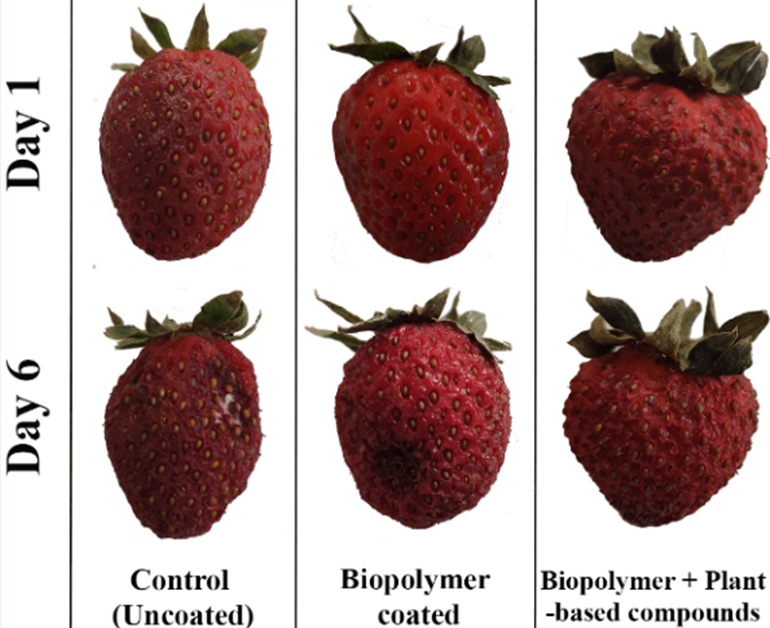

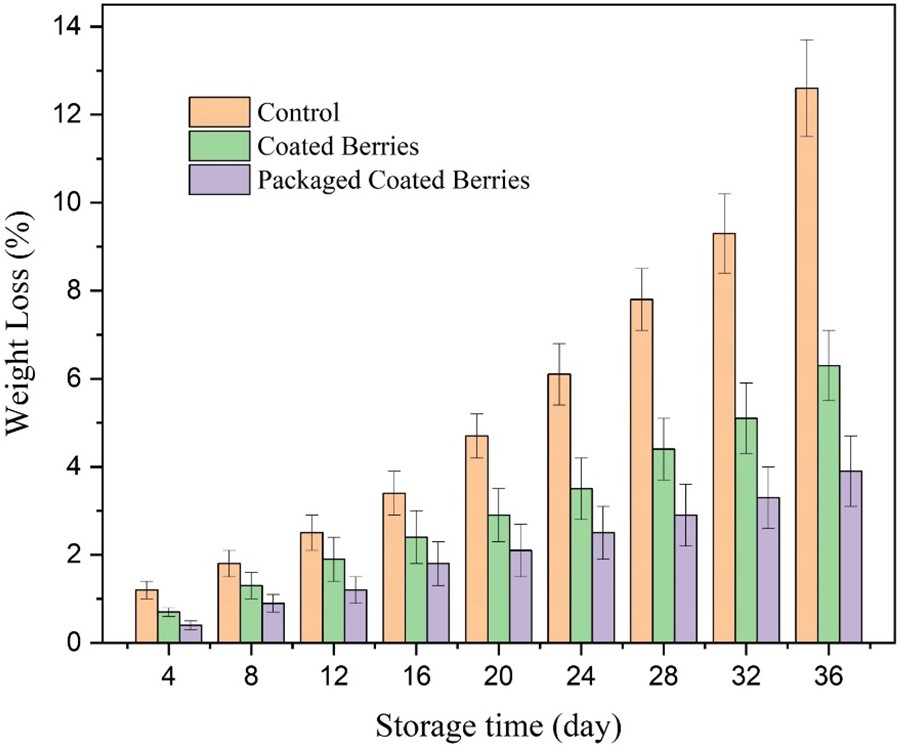

BerryCoat’s solution increases shelf-life 2-3 times

compared to the control fruits through the following

features:

1. Edible Coatings

- Prevents contamination.

- Kills microbes.

- Preserves flavour and nutrients.

2. High-Barrier Packaging

- Prevents contamination.

- Prevents damage from gases and UV.

- Safe and waste-free.

Product

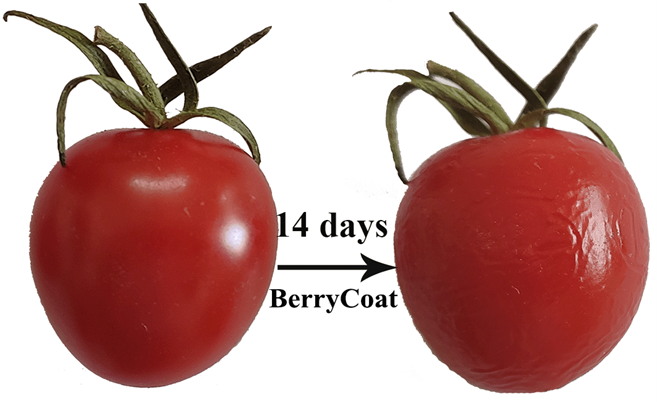

BerryCoat is a two-barrier packaging system. The first layer is an edible coating on the berry. The second layer is a nano composite film which prevents damage from gases and UV. The motive is to develop a large-scale packaging system to effectively improve the preservation of fruits’ nutrition during the storage and export periods.

Production Process

- Extraction of essential oils and extracts: Extract essential oils from plants.

- Fabrication of bio composite solution: Make a water-based solution. It is a mix of sugars, proteins, and lipids.

- Coating application: Dip and/or spray the coating on the berries.

- Transferal to biodegradable nanocomposite packaging: The coated berries are transferred to the pre-made nano-composite bio-packaging.

Applications

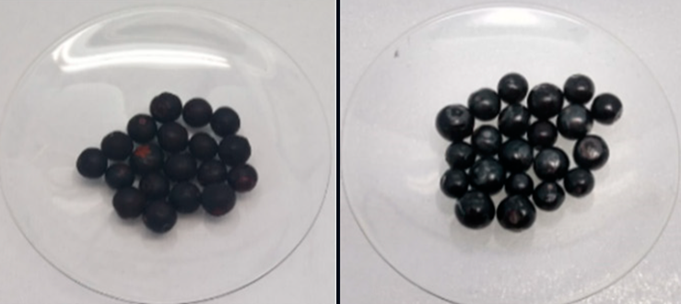

BerryCoat could be applied in different ways depending on the type of fruits or vegetables. In case of the berry family, the harvested berries are immersed into the BerryCoat solution for a pre-optimized time interval, removed and dried on specific sieves, and then, is transferred to the packaging unit. BerryCoat has also designed a more efficient coating method using the spraying technique in which the BerryCoat solution is sprayed onto the surface of berries which are slowly moved on a shaking bed. The level of shaking and moving speed is adjusted in a way that a thin layer of BerryCoat covers the whole surface of fruits. In the packaging unit, the second barrier of BerryCoat is applied to the coated berries. They are placed in biodegradable and transparent packages in different sizes (100-1000 g). The top surface of the packaging is then sealed with a high barrier flexible nanocomposite film.

Technology Used

Barrier Packaging System

First Barrier

The first barrier is an edible composite coating, incorporated with essential oils and plant extracts, which is applied on the berries’ surface in the form of a thin uniform film and acts as a strong barrier toward transmission of different gases. The coating is edible and can be easily washed away before use. The applied edible coating imparts a significant antimicrobial and antifungal behavior to the fruits’ surface. The edible coating stops microbial contamination and moisture loss. This increases shelf-life and keeps in the nutrients. The berries also keep their flavor and firmness. Moreover, the improved impermeability toward water vapor led to the retainment of the fruit moisture keeping their stiffness and freshness for a longer period of time. The overall effect of the applied coating is the prolonged storage period of the berries which can lead to a significant reduction in the number of wasted berries around the globe.

Second Barrier

Antimicrobial Protection

Shelf Life

BEFORE/AFTER