Oishii Launches Koyo Berry!

In a groundbreaking move, vertical farming leader Oishii has introduced the Koyo berry, the latest addition to its strawberry lineup.

BerryCoat, a Canadian chemical and agricultural research firm, is dedicated to developing an innovative large-scale packaging solution aimed at enhancing the preservation of fruit nutrition during storage and export. Recognizing the unique preservation needs of different agricultural products, BerryCoat’s primary emphasis is on creating a highly effective and environmentally sustainable edible packaging system with dual-barrier protection tailored specifically for blueberries, Canada’s leading fruit export valued at $550 million. What sets BerryCoat apart from other commercial offerings is its formulation, meticulously designed to provide optimal protection for fruits.

To become a global leader in eco-friendly fruit packaging, setting new standards for quality, sustainability, and innovation while emphasizing the health and well-being of the users.

To develop an innovative technology to simultaneously achieve advanced sustainable nutrient-preserving packaging that is cost-effective, edible, and highly efficient.

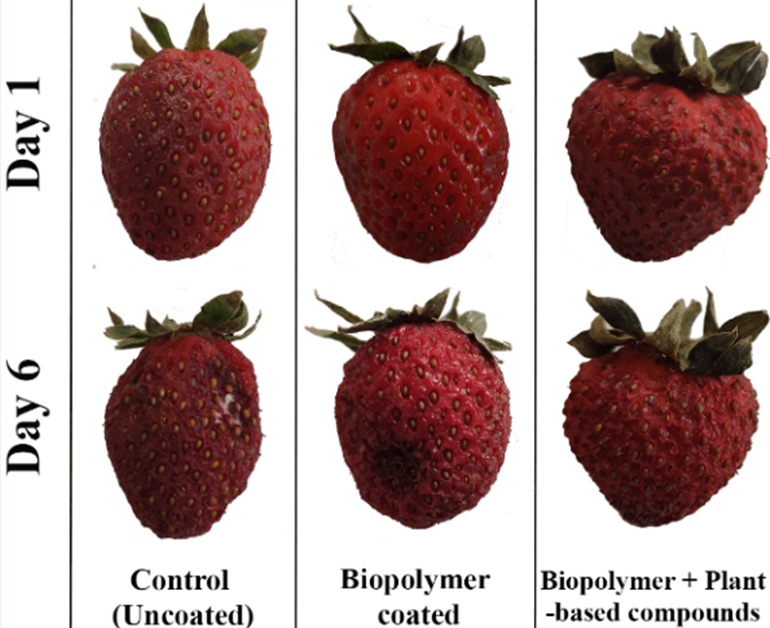

Post-harvest losses are one of the major concerns in the fruits and vegetable markets across the world. This issue negatively impacts the profitability of farming vendors and farmers. One of the major reasons for the post-harvest losses is the spread of post-harvest diseases due to the pathogen activities among fruits and vegetables. As a result, the demand for an effective post-harvest protection system increased, including the application of fruit and vegetable coatings.

In Canada, blueberries are the number one fruit export, and deal with post-harvest losses as well.

Additionally, the waste of fruit causes excessive use of cooling systems, storage, and transport systems which are very expensive.

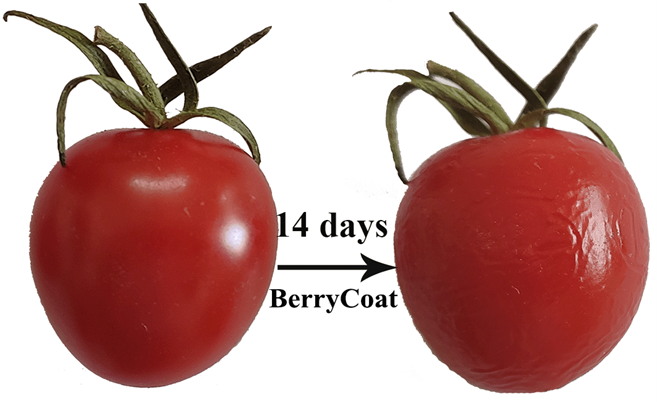

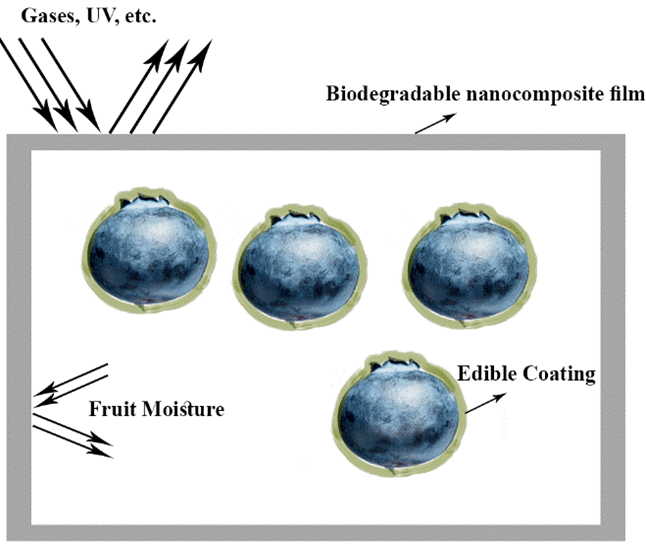

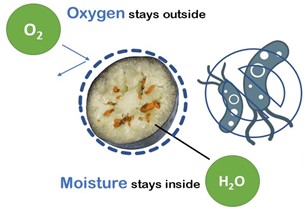

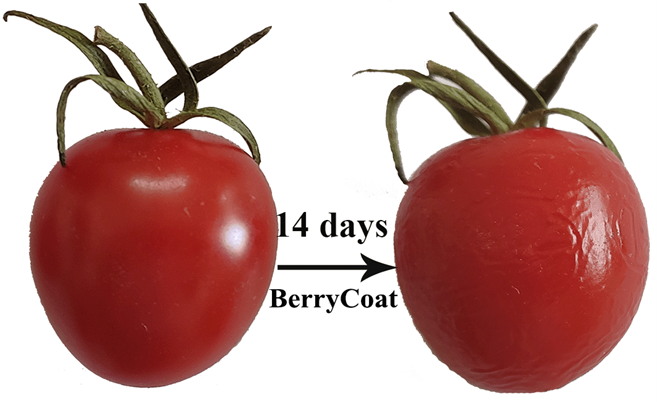

BerryCoat’s solution is an eco-friendly edible, two-barrier protection packaging system utilizing essential oils and extracts with nanocomposite technology. The first layer is an edible coating on the berry. The second layer is a nano composite film which prevents damage from gases and UV. BerryCoat is also good for the environment, as the product is fully biodegradable.

BerryCoat is a two-barrier packaging system. The first layer is an edible coating on the berry. The second layer is a nano composite film which prevents damage from gases and UV. The motive is to develop a large-scale packaging system to effectively improve the preservation of fruits’ nutrition during the storage and export periods.

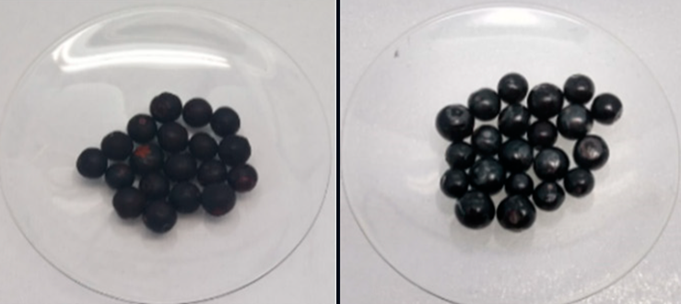

BerryCoat could be applied in different ways depending on the type of fruits or vegetables. In case of the berry family, the harvested berries are immersed into the BerryCoat solution for a pre-optimized time interval, removed and dried on specific sieves, and then, is transferred to the packaging unit. BerryCoat has also designed a more efficient coating method using the spraying technique in which the BerryCoat solution is sprayed onto the surface of berries which are slowly moved on a shaking bed. The level of shaking and moving speed is adjusted in a way that a thin layer of BerryCoat covers the whole surface of fruits. In the packaging unit, the second barrier of BerryCoat is applied to the coated berries. They are placed in biodegradable and transparent packages in different sizes (100-1000 g). The top surface of the packaging is then sealed with a high barrier flexible nanocomposite film.

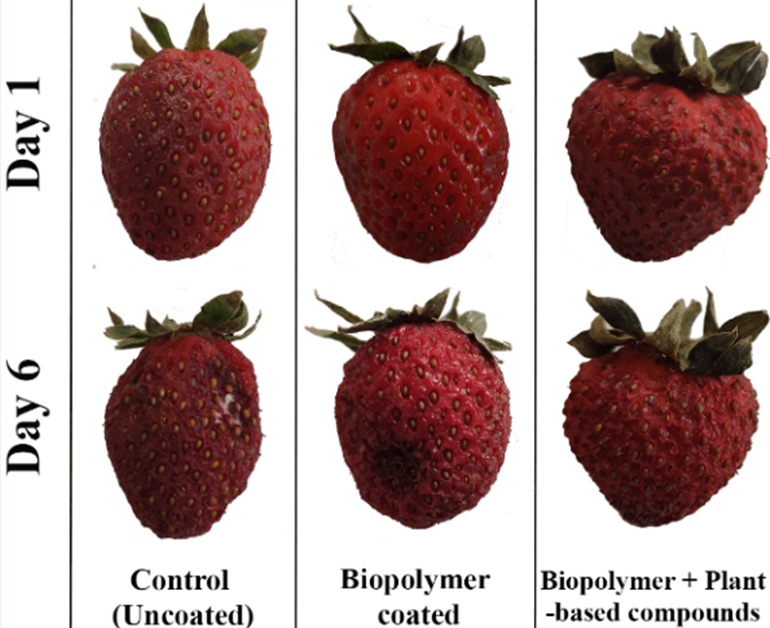

The first barrier is an edible composite coating, incorporated with essential oils and plant extracts, which is applied on the berries’ surface in the form of a thin uniform film and acts as a strong barrier toward transmission of different gases. The coating is edible and can be easily washed away before use. The applied edible coating imparts a significant antimicrobial and antifungal behavior to the fruits’ surface. The edible coating stops microbial contamination and moisture loss. This increases shelf-life and keeps in the nutrients. The berries also keep their flavor and firmness. Moreover, the improved impermeability toward water vapor led to the retainment of the fruit moisture keeping their stiffness and freshness for a longer period of time. The overall effect of the applied coating is the prolonged storage period of the berries which can lead to a significant reduction in the number of wasted berries around the globe.

CEO

Mr. Nguyen Tuan Vuong is an outgoing and result-driven senior business executive with 12 years of leadership experience and 20+ years of experience in agricultural commodities supply chain management. He has worked as a Purchasing Supervisor Cum Technician, Purchasing Manager and Cocoa Team Lead. As Chief Executive Officer of BerryCoat, Mr. Nguyen Tuan Vuong’s result-driven passionate mindset, past leadership roles in the food industry, and people relations experiences will be crucial for its ability to succeed in Canada.

CMO

Mr. Phan To Hong Hai is a hardworking and detail-oriented marketing and advertising executive, and real estate entrepreneur with 30+ years of experience in marketing and media. He has worked as a Traffic Controller Manager, Account Manager, Senior Account Manager, Communication Manager, Vice General Director, Business Development and Marketing Director, Sales and Marketing Manager, Vice General Manager, Marketing and Communication Director and Head Of Education. As Chief Marketing Officer of BerryCoat, Mr. Phan To Hong Hai’s extensive experience in leadership positions within marketing, sales, and advertising fields will be vital for the Company’s ability to build brand awareness within Canadian markets.

CTO

Mr. Ngo Minh Cuong is an ambitious scientific sales entrepreneur with more than 10 years of experience in science equipment trading and 20 years in scientific/medical instrument sales/services. He has worked as a Customer Engineer, Deputy Technical Manager, Founder/Director and owner – operator. As Chief Technical Officer of BerryCoat, Mr. Ngo Minh Cuong’s remarkable ability to network and use technology to enhance Company objectives will ensure BerryCoat’s success in Canada.

In a groundbreaking move, vertical farming leader Oishii has introduced the Koyo berry, the latest addition to its strawberry lineup.

The nutritional advantages of berries are undeniable, given their abundant antioxidants, high flavonoid content, and various health benefits

Did you know that blueberries rank as the leading fruit commodity in Canada in terms of both growing area and farm gate value? Over the past decade, the acreage dedicated to both wild (low bush) and cultivated (high bush) blueberries has seen a notable increase.

With the emergence of this innovative packaging solution, it’s worth delving into the reasons behind its increasing popularity compared to traditional packaging methods.

Phytonutrients represent organic compounds derived from plants that exert influence over our genetic activity.

Julia Zumpano, a registered dietitian (RD) and licensed dietitian (LD), offers valuable insights into the advantages of incorporating blueberries into your diet.

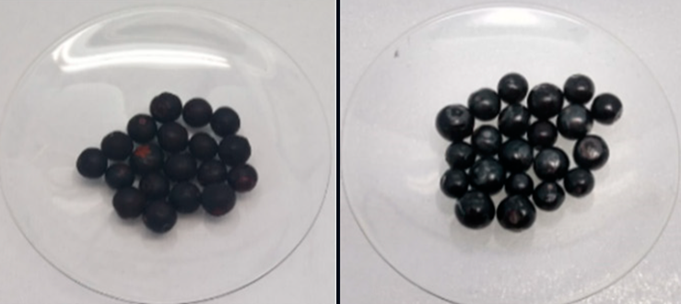

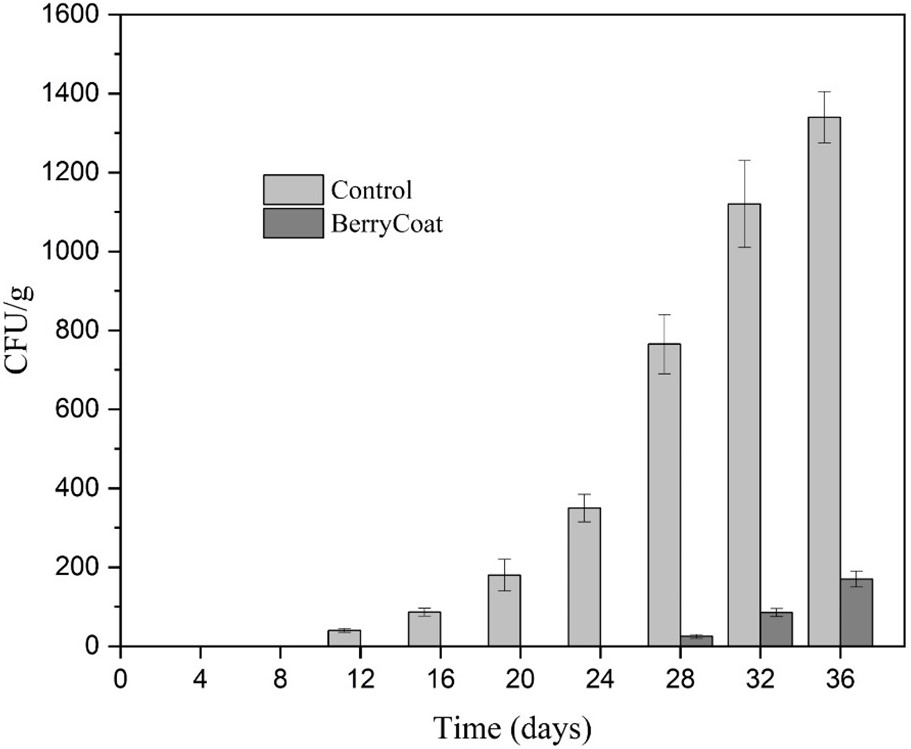

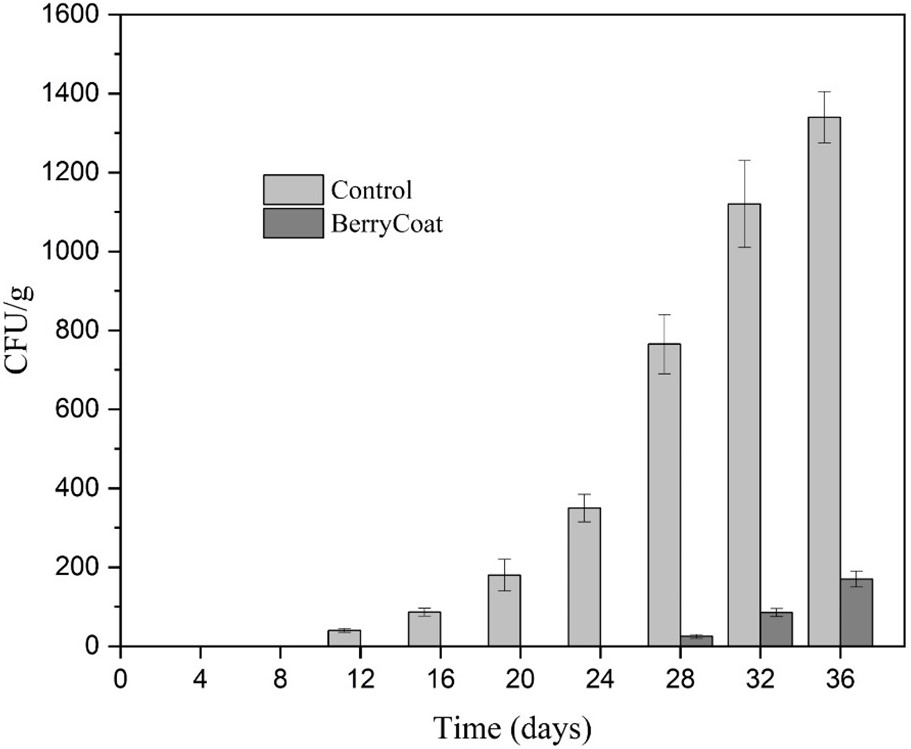

Prevent and Growth for 28 days

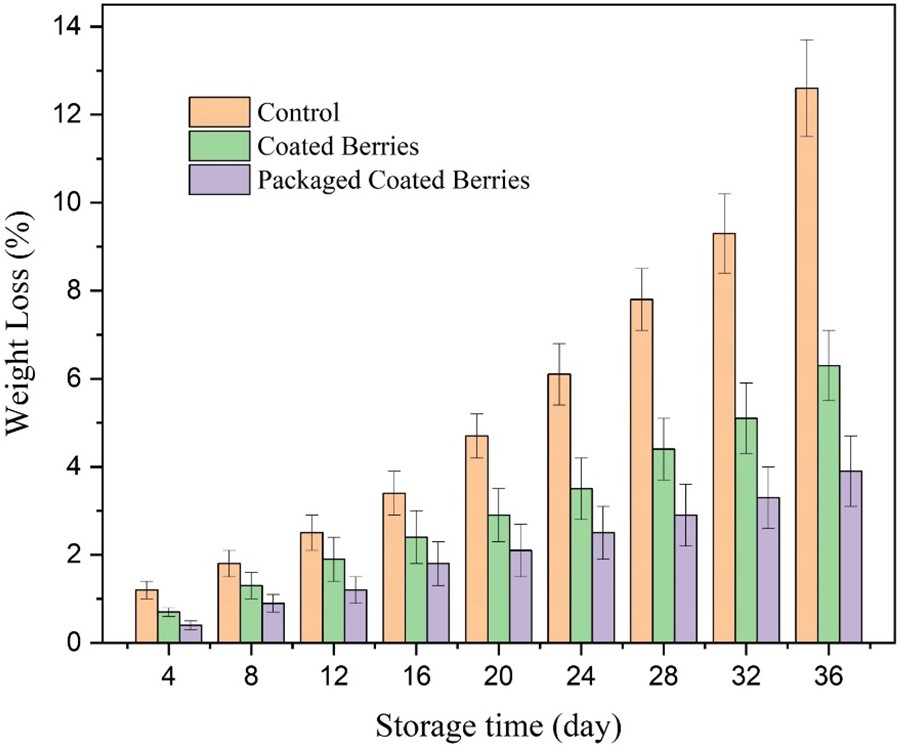

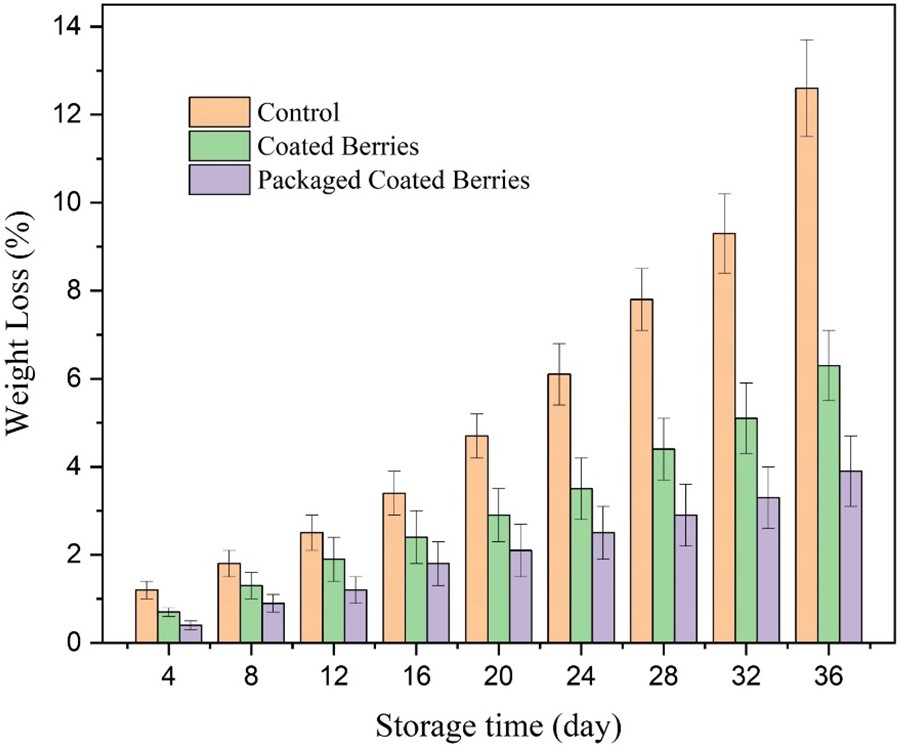

Prevent and Growth for 28 days Dramatically less dehydration

Dramatically less dehydration